We describe the BCAM (Boston CCD Angle Monitor) camera and integrated light sourcees in the BCAM User Manual. Here we describe light sources without cameras that we intend for use with BCAMs. In some applications, we have no space for a BCAM with its camera and integrated sources. In such applications, we can often obtain adequate monitoring with a pair of light sources, which we then view with a BCAM from elsewhere. We call such arrangements of sources without cameras source plates. Here we present various BCAM source plates and describe how we calibrate them. We show how we can calibrate JK-Plates both in a roll-block and on a granite beam.

The JK-Plate comes in two varieties: the J-Plate and the K-Plate. One is the mirror image of the other. Both are black anodized rectangles of aluminum. You will find a detailed drawing of the J-Plate here. We show an extract from the drawing below.

To drive the lasers in the J-Plate, we use the Azimuthal BCAM Side Head (A2049M). The K-Plate is the mirror image of the J-Plate. We use the A2049N to drive its lasers.

The JK-Plate has two holes in the bottom edge that allow us to screw it onto a base plate, which in turn mounts upon a set of three balls. In the ATLAS experiment, we call these base plates azimuthal source plates, and each of them carried one J-Plate and one K-plate, with the sources shining in opposite directions. We use them to monitor movement of muon-detecting chambers in the direction of the particle beam.

The J-Plate has its own coordinate system, with its origin on the top-right corner, at the front side of the plate, which is the one in which the laser light will shine. You can see in the above drawing that each source is marked L or R, but the L and the R are the wrong way around in the front view. There is no good reason for this reversal. The y-axis runs along the top edge of the plate. The x-axis perpendicular to the face of the plate. The z-axis is downwards, to complete a right-handed system. The K-Plate is similar in its coordinate system, but the origin is the top-left corner and the z-axis is upwards.

These JK-Plates are designed for calibration on a roll-block in much the same way that we calibrate the sources built into BCAMs, which we describe elsewhere. We mount the JK-Plates in a brass block by pressing them against three pins, two along the top edge of the plate and one along the side edge nearest the sources. We view the sources in the roll-block with a reference camera that happens to be mounted in our BCAM calibration roll-cage, as you can see in the photograph below.

We measure the locations of these pins in the four orientations of the roll cage. We make these measurements with a CMM and we express them in terms of the mounting coordinates defined by the three mounting balls upon which the roll-block sits. We record the positions in an apparatus measurement like the one below for the J-Plate roll-block.

apparatus_measurement:

calibration_type: j_plate

apparatus_version: BLOCK_J_V4

measurement_time: 20090523000000

operator_name: Kathryn

data:

59.393 27.314 20.799 27.322 12.825 41.290 {0 degree Pin1, Pin2, Pin3}

37.687 66.778 37.685 28.184 23.720 20.205 {90 degree Pin1, Pin2, Pin3}

-1.747 45.092 36.847 45.088 44.826 31.120 {180 degree Pin1, Pin2, Pin3}

19.928 5.644 19.930 44.236 33.896 52.215 {2700 degree Pin1, Pin2, Pin3}

16.451 {magnification in mm/mm}

-3.54 {rotation in mrad}

6.350 {diameter of pins in mm}

-3.730 {source x-coordinate in mm}

end.

The roll-block is mounted upon a micrometer stage. We calibrate the micrometer on this stage with the help of our CMM. We move the roll-block by 10 mm, taking images of two sources every 500 μm. The size of the movement of the images tells us the magnification of the image at the range of the roll-block. The direction of movement gives us the rotation of the micrometer stage with respect to the image. Our setup is such that the movement of the micrometer stage is parallel to the global horizontal axis to within 100 μrad. Thus we obtain both the rotation and magnification of the image with one micrometer stage measurement.

We take images of the two sources in four orientations of the roll-block. We determine the positions of the image spots in each image. We apply a geometric calculation to obtain their positions with respect to the top-right corner (in the case of a J-Plate) or top-left corner (in the case of a K-Plate). We perform this calculation in the bcam_jk_calib routine, which you will find in our calibration source code, bcam.pas. We record spot positions in device calibrations like this one.

device_calibration: device_id: J0670 calibration_type: j_plate apparatus_version: BLOCK_J_V3 calibration_time: 20090717115242 operator_name: Alex data: 962.85 1059.45 1936.31 1055.05 1458.30 1552.62 1452.85 578.48 1952.04 1055.63 978.46 1060.64 1454.53 561.85 1459.87 1536.30 end.

We perform the roll-block calibration procedure with the help of the BCAM Calibrator Tool, which you will find in the LWDAQ software. We calculate the source locations of many plates at once using the BCAM Calculator. We store the device calibration measuremets in a file, separate from the apparatus measurements, and combine them with the BCAM Calculator to produce a file of source positions. You will find the apparatus measurements on the web in our apparatus database, the calibration measurements in calibration database, and the calculated parameters in JKP Parameters.

Here are examples of J-Plate and K-Plate calibration constants: they give the coordinates of the left and right sources for each plate in the local coordinates of the plate. For the x-coordinate, we use the nominal position of the source in that direction, just as we do for BCAM sources.

J0271 20050921135604 -3.730 4.719 5.650 -3.730 20.811 5.654 J0272 20050921140701 -3.730 4.696 5.696 -3.730 20.716 5.688 K2046 20090715163006 -3.73 20.705 -5.753 -3.73 4.742 -5.743 K2047 20090715163147 -3.73 20.705 -5.753 -3.73 4.742 -5.743

Here we have the plate serial number, followed by a time stamp, then the coordinates. We see that the J-Plate sources have a positive y-coordinate while the K-Plate sources have a negative y-coordinate, because of the different manner in which the plate coordinates are defined.

When we mount a JK-Plate in the roll-block, we press it against three pins. Two pins locate and orient the top edge of the plate. The third pin locates the edge closest to the sources. Together, the three pins locate the origin of the plate coordinate system precisely with respect to the roll-block. You will find our calculation of the origin and axis unit vectors from the pin locations in the bcam_jk_coordinates_from_mount routine of bcam.pas. The routine draws a line through the top pins and finds the shortest vector from the third pin to this line. We now have an intersection. We displace this intersection one pin radius along the top line and one pin radius along the shortest vector, both in the direction of the plate. The intersection now lies at the reference corner of the plate, assuming the plate is square. The y-axis is parallel to the line joining the first two pins. The z-axis is parallel to the shortest vector. The x-axis completes the right-handed coordinate system.

We find that the resolution of the JKP roll-block procedure is a few microns rms, taken over ten repetitions with the same plate. When we perform the calibration, we must slide the plate up against its three alignment pins and we must place the roll block accuratly in four orientations. Furthermore, the spot positions themselves have a resolution of around 0.2 μm which is magnified by 16 to become 8 μm in terms of source position. We cannot determine the absolute accuracy of the roll-block calibration until we can compare it to an independent measurement, which is why we embarked upon our experiments with rotation on the granite beam.

We can calibrate rectangular source plates with the help of a granite beam. We don't need a roll-block, even though a roll-block is a fine way of performing a calibration once you have it set up. Calibration on the granite beam is also based upon rotation of the plate, but we rotate only by 180°.

If we rotate a source plate with known, rectangular dimensions by exactly 180° and measure how far each light source in the plate moves, this movement tells us how far from the center of the plate the light source must be. Because we know the dimensions of the plate, we can determine the absolute location of its sources with respect to its corners.

To make this procedure straightforward, we work on a granite beam. We use a straight edge as a good edge up to which to press our plates. Our apparatus is similar to the apparatus we used to calibrate BCAM cameras and sources on a granite beam, which we describe elsewhere. To give us the magnification of our images we use a BCAM whose sources we calibrated precisely by other means, and whose separation we know to within 0.05%.

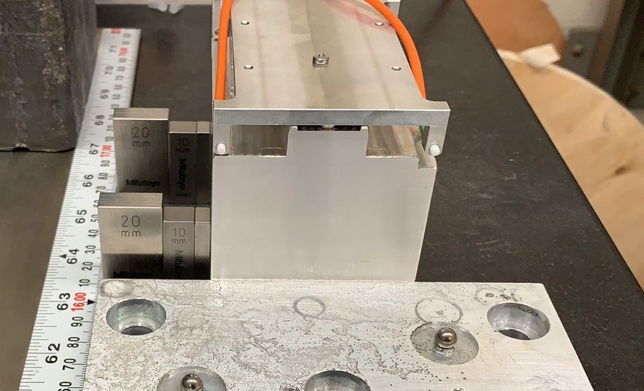

Here is a photograph of our apparatus on a granite beam. It is similar to the apparatus we used to calibrate CBAM cameras and sources on the granite beam, as you can see here. In this case, we do not move the sources along the straight edge. We use the straight edge only as a stationary point up against which we press our plates, and we use the ruler along the straight edge to make sure that we place our components at the correct range from one another.

Because the JK-Plates are so thin (only 4.8 mm thick), we must force them to remain in a vertical position when we press them up against the straight edge and take images of them with our viewing camera. We use square aluminum rod as a weight. We hold our cameras and cables in place with other weights.

Here is the view of the J-Plate sources from the viewing camera when the light baffle is removed. We see reflections of the sources off the granite surface. Note that this image is inverted because it comes from an azimuthal BCAM.

The baffle blocks the reflections, which means that our data acquisition is more tolerant of source plates in which one laser is much brighter than the other.

We take a Blue Azimuthal BCAM (20MABNDB000012) and place it against the straight edge with its front face at position 100 mm as marked on the tape measure. This BCAM provides us with our viewing camera. We take a Black Polar BCAM (20MABNDL000001), and place it at position 1498.3 mm. This BCAM provides us with our reference sources. Both these BCAMs have been calibrated in the roll-cage. In particular, we know the separation of the sources on the Black Polar BCAM is 15.990 mm, give or take a few microns. We take ten images of the reference sources with the viewing camera. The separation of the spots gives us the magnification of our image for sources at this precise range. We get 53.369 um/mm.

We remove the Black Polar BCAM and put a square of aluminum against the straight edge, to provide an inner corner to locate our source plates. We fix the square in place with a lead weight. We locate the edge of the square at 1500.0 mm along the tape measure. The BCAM sources are set 5.4 mm back from their front face, while the JK-Plate sources are only 3.7 mm back from their front face. That's why we place the Black Polar BCAM at 1498.3 mm, so as to give us the magnification for JK-Plate sources at 1500.0 mm.

In our measurement of magnification and rotation, we believe it would be sufficient to have a gauge block of exact 10-mm thickness to displace a J-Plate by 10 mm from the straight edge. This movement would allow us to deduce magnification and rotation in one step, with no need for a pair of reference sources.

We slide the JK-Plate across the field of view of the viewing camera in half-millimeter steps. We take an image at each step. The slope of the line made by the image spots is the opposite of the rotation of the image sensor with respect to the granite table. We get 2.2 mrad.

We take a J-Plate, number J0679, and measure it ten times in width and height. We get 49.00 mm and 21.62 mm. We press it up against the straight edge and take an image. We rotate it and take another image. We calibrate, with a spreadsheet, the position of the sources in each case. After some practice, we obtain a resolution of 2 μm in the horizontal direction and 6 μm in the vertical direction. The trick is to get the plate to sit vertically on the beam, despite being so thin.

We prepare a LWDAQ Tool called Sources Granite that makes the measurement process easy, stores measurements to disk, calculates the source positions in batchs, and compares the source positions to those calculated by other means. In our case, we had the roll-block measurements in a file and we compared these to those we obtained with the granite beam. We calibrated all thirty or so J-Plates we had on hand. Here is a plot of the difference between the two as a function of the deviation of the coordinate from its mean value.

The average difference is +13 μm and +2 μm in y and z for the left source, and +2 μm and −25 μm for the right source. The standard deviation of the differences are around 15 μm.

We calibrated thirty or so K-Plates using the same stand. The code is slightly different for the K-Plate because the z-axis is upwards and the coordinate origin is on the opposite corner. The average difference is −4 μm and −19 μm in y and z for the left source, and +3 μm and +14 μm for the right source. The standard deviation of the differences are around 15 μm.

We now set up a Black Azimuthal BCAM, number 20MABNDA000012, at 1500.0 mm and move our Black Polar BCAM to 101.7 mm. We proceed to set up a mirror image of our original apparatus. We call the original the B-Stand (after the B in the viewing camera serial number), and the second the A-Stand. After a couple of days hunting down bugs in our calculations, we re-calibrate all the J-Plates on the A-Stand.

The average difference between the A and B calibrations is +8 μm and +7 μm in y and z for the left source, and +0 μm and +0 μm for the right source. The standard deviation of the difference is around 15 μm.

We are well-pleased by the agreement between these two stands. The agreement suggests that the calibration is accurate to around 20 μm rms, which is our ATLAS requirement. The procedure takes only one minute per plate, so we can repeat it to detect errors of placement.

Our comparison with the roll-block shows that all three calibrations are in agreement to better than 30 μm rms, which suggests that the roll-block must be accurate to better than 30 μm rms. We cannot confirm that the roll-block is accurate to our required 20 μm rms.

A fiber source plate uses a multi-mode fiber to bring light to the tip of a cylindrical ferrule. In the photograph below we see two such ferrules glowing with red laser light that has been coupled into the far end of the fiber with two lenses.

The light source is the 62-μm diameter core of a 125-μm diameter multi-mode, radiation-hard optical fiber. The core is centered within ±3 μm of the center of the outer surface. The tip has been glued into a zirconia ferrule and polished flat at the tip. The ferrule has a hole down the center that is 126 μm in diameter and centered to ±3 μm. We measure these protruding ferrules to 2-μm precision with our CMM, and so obtain the postion of the center of the fiber with accuracy of order 10 μm and resolution better than 2 μm.

The fiber source plates mount upon three steel balls arranged in the same way as for J-K Plates and BCAMs. The CMM measures the balls and then the ferrules and produces for us the coordinates of the fiber tip in mount coordinates. We keep a record of the CMM calibrations in FSP Parameters. Each line has the serial number of the source plate, the date of calibration, and the three coordinates of the fiber tip. For both black and blue source plates, we give the coordinates of the left-hand source first and the right-hand source second, as seen from the front of the plate.

We checked the CMM calibration on our granite beam using a procedure similar to the one we used with the J-K plates. Our calibration program is FSP Calibration. The granite beam procedure had resolution a few microns and absolute error of order ten of microns, and was consistent with the CMM calibration.

[02-SEP-20] We make the following source plates for the ATLAS New Small Wheel (nSW), in a narrow and a wide variety, both of which mount on standard BCAM mounting plates.

The 30-mm source plates are of the same design. All the source plates have the same pair of sources on front and back faces. When we use Aramys to reconstruct the positions of source, cameras, and alignment balls in the partially-constructed nSW, we find that the apparant location of the optical sources appears to be 0.6 mm inside the ferrule, rather than exactly at the face of the ferrule, as we show in ARAMyS Source Plate Calibration Study.