Parts:

- Box

- Mask, Size #340

- Front Spacer, about 4.5mm thick

- Diffuser

- Middle Spacer

- Electronics, A2045

- Lid

- Base

- Screw Pan Philips M3x8, McMaster 92000A118

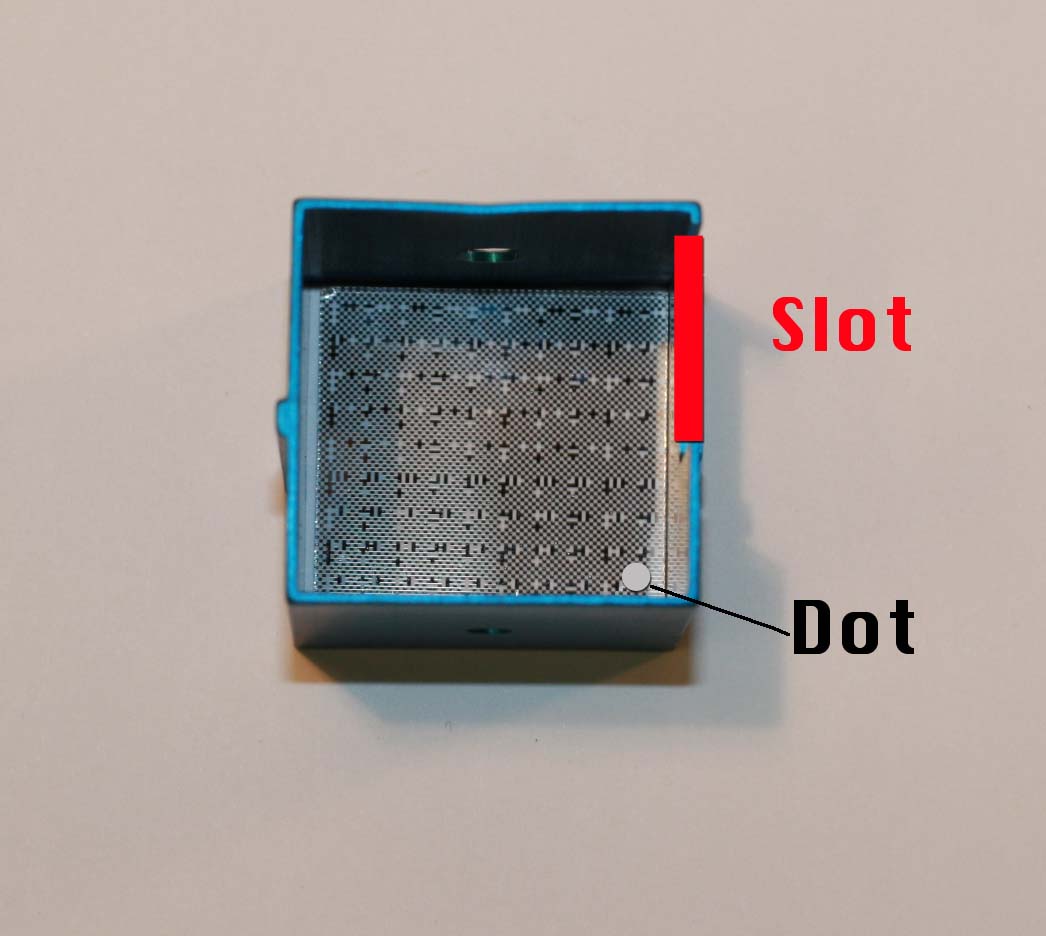

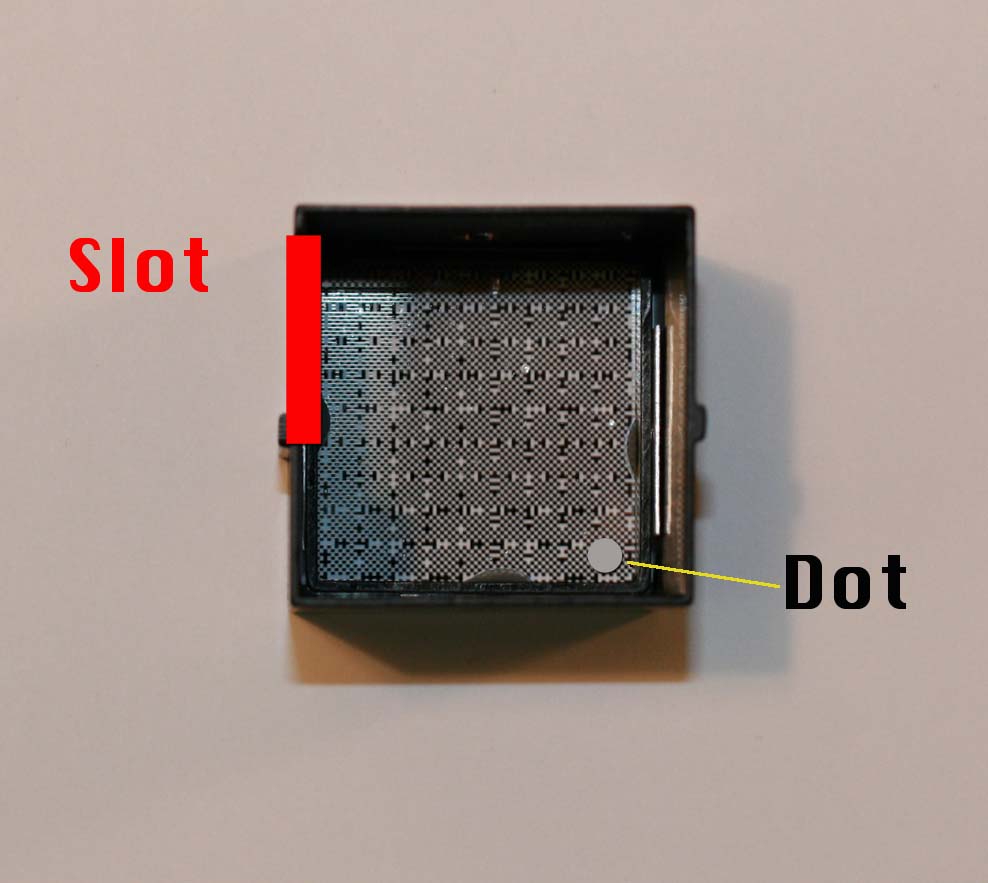

- Dot Marking Mask Orientation

- O-Ring, Viton AS568A-005, McMaster: 9464K105

This manual briefly describes how to assemble RASNIK Bar Masks.

|

Parts:

|

|

Figure 1: Diagram of a Black Bar Mask. |

|

Before you epoxy anything, run through all the steps to make sure the parts you are working with fit together properly.

Step: 1

Step: 2

Step: 3

Step: 4

Step: 5